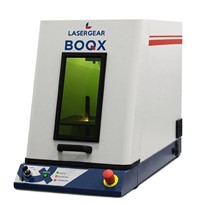

AJAX Fiber Laser Marking Machines

Suitable for Aluminium, Stainless Steel, Brass, Copper, Nylon, ABS, PVC, PES etc.

Models from 20 watts to 100 watts

Standard Fiber laser or MOPA models.

Split type, Fully Enclosed or Hand Held.

Optional;

Auto Focus,

2 axis Work Table,

Rotary Devices,

Various Size Lenses,

Part Recognition,

European CE and USA FDA Approved.

Principle and composition of fiber laser marking machines:

Fiber laser marking machine uses laser beam to make permanent marks on the surface of various materials. The effect of marking is to expose the deep material through the evaporation of the surface material, or to "carve" traces through the chemical and physical changes of the surface material caused by light energy, or to burn off part of the material through light energy to show the required etching patterns, texts, barcodes and other graphics.

The so-called fiber laser marking machine means that the marking machine uses a fiber laser. The fiber laser has the characteristics of small size (no water-cooling device, air cooling), good beam quality (fundamental mode), and maintenance-free.

It is mainly composed of three parts: laser, vibrating lens and marking card. It uses fiber laser to produce laser marking machine. The beam quality is good. Its output center is 1064nm. The life of the whole machine is about 100,000 hours.

Compared with other types of laser marking the life of the device is longer, and the electro-optical conversion efficiency is more than 28%. Compared with other types of laser marking machines, with conversion efficiency of 2%-10% fiber has a great advantage. It has outstanding performance in energy saving and environmental protection.

Features:

1. It can process a variety of metal and non-metal materials. Especially for high hardness, high melting point, brittle materials, marking is more advantageous.

2. It belongs to non-contact processing, does not damage the product, has no tool wear, and has good marking quality.

3. The laser beam is thin, the processing material consumption is small, and the processing heat affected zone is small.

4. High processing efficiency, computer control, easy to realize automation.

Main feature:

Fiber lasers are divided into two categories: continuous fiber lasers and pulsed fiber lasers. According to the power size:

1. Continuous 5W, 10W, 20W to 400W, 4000W; (mainly used for cutting or welding or

cladding)

2. Pulse 10W, 15W, 20W, 25W, 30W to 50W, 100W. (Mainly used for marking or cleaning)

|

Parameter |

|||

|

Name |

Performance |

||

|

Fiber Laser Engraver |

20W |

30W |

50W |

|

Beam quality |

M2:1.2 M^2 is a parameter that defines the quality of the laser beam. The closer to 1 the better the beam quality. M^2=Actual beam waist radius*distant factory diffraction angle/theoretical beam waist radius*theoretical diffraction angle |

||

|

Average output power |

20W |

30W |

50W |

|

Adjustable output power range |

10%-100% |

||

|

Maximum linear marking speed |

7000mm/s |

||

|

Laser wavelength |

1064nm |

||

|

Marking range (field lens) |

110×110 mm / 150×150mm / 175×175mm |

||

|

70×70 mm / 300×300mm Option |

|||

|

Laser model |

RAYCUS,JPT / IPG(option) |

||

|

Laser repetition rate |

20KHz-80KHz@RAYCUS 1-400KHZ@JPT 1.6-1000kHZ@IPG |

||

|

Minimum character height |

=0.2mm |

||

|

Marking depth |

=0.2mm |

=0.4mm |

=1mm |

|

Maximum material thickness (the smaller the field lens, the more concentrated the beam, the greater the thickness of the workpiece that can be placed) |

300mm @110×110 mm 250mm @150×150 mm 206mm @175×175 mm |

||

|

Repeatability |

0.002mm |

||

|

Minimum line width |

0.01mm |

||

|

electricity demand |

110V-240V/50Hz-60Hz |

||

|

Power consumption of the whole machine |

<500w |

<800w |

<1000w |

|

Cooling system |

Air cooling |

||

|

Package Size |

785*505*775mm (Wooden) |

||

|

Gross weight |

63KG-66KG |

||

Application areas:

Widely used in integrated circuit chips, computer accessories, industrial bearings, watches, electronic and communication products, aerospace devices, various auto parts, home appliances, hardware tools, molds, wires and cables, food packaging, jewelry, tobacco, and military affairs, etc. Field graphics and text marking, and mass production line operations.

Fiber laser marking machine can achieve:

1. Alumina black, this is the MOPA technology fiber laser marking machine that needs pulse width adjustable. Different from ordinary fiber laser marking machine, this fiber laser marking machine can make alumina black, while general fiber laser marking machine cannot do this;

2. Metal colouring, this requires some adjustments and attempts on the parameters according to the material, and various colours can be printed on stainless steel;

3. Metal blackening is similar to the second point;

4. On-line flying marking, what does this mean, that is to combine the fiber laser marking machine with the assembly line, marking while feeding, so that we can greatly improve our work efficiency, for some needs to be placed on the assembly line Marking is an absolute boon for marking items that are generally inconvenient to move manually;

5. Portable fiber laser marking machine, this kind of laser marking machine is small, does not occupy space, and can meet the basic marking needs. For customers with low marking requirements, the portable laser marking machine is very suitable.

From the material point of view:

The fiber laser marking machine has great advantages for marking hard, brittle, and dark materials. In other words, most metal materials, as well as some specific non-metal materials such as plastics, can be marked by fiber laser marking machines.

The marking effect is subject to the actual effect. In fact, some materials such as hard plastic, CO2 laser marking machine and fiber laser marking machine can all be marked, but the effect is different. Of course, the prices of the two machines are also different. So customers need to choose according to their own production requirements and cost control.

-720x400.jpg)

-205x205.jpg)