Workers in Australian workplaces are exposed to vibration in many job roles.

Industries like mining, construction, farming, agriculture, forestry and fisheries, trades, and utilities are high-risk industries for vibration exposure through hand tools, power tools, machinery and heavy vehicles.

The EU Vibration Directive 2002 was key in promoting awareness about vibration hazards in the workplace. Vibration reduction initiatives are supported by legislation in the EU, and maximum vibration exposure is limited at a value of 5 m/s2 for HAV, with employers required to take actions to minimise risk and introduce health monitoring at 2.5m/s2

Some Australian Standards such as AS 2763-1988 and AS2670 - 2001 offer information about HAV, as well as WBV and measures of evaluation of exposure. All major research works and commissioned reports undertaken to date for the region however, recommend investigations into a benefit analysis of the adoption of minimum legislative requirements for vibration exposure.

The stats

Around 24 per cent of Australian workers were exposed to vibration in the workplace, of which 43 per cent of exposure was to HAV, 38 per cent to WBV, and 17 per cent to both, according to one of the few studies commissioned in Australia to study such impacts, the 2008 National Hazard Exposure Worker Surveillance (NHEWS) survey.

A key problem identified was the small percentage of workers who were given any training at all and the large number of smaller workplaces that had no control measures in place for vibration reduction.

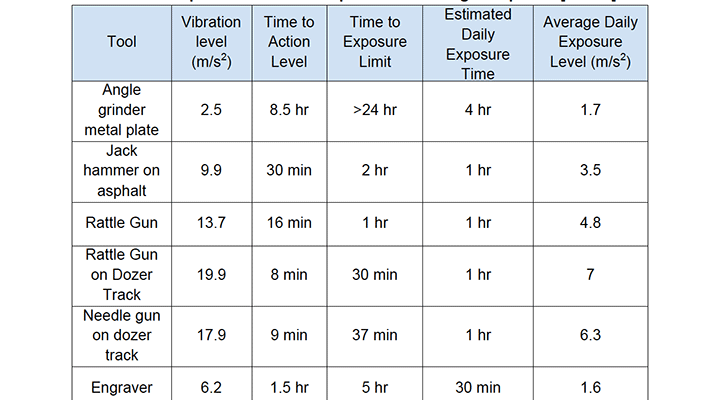

Some examples of vibration level exposures in Australian mining workplaces, as measured by Gary Foster in Assessment of Vibration Exposure in the Mining Industry, even exceed limits as per EU directives. As a result of these calls, Safework Australia took a significant step forward in 2012 that saw the production of two factsheets outlining a code of practice for both HAV and WBV.

Long-term effects

Long-term exposure to the more common form of vibration HAV results in a serious condition called Hand Arm Vibration Syndrome (or Vibration White Finger) often manifesting with a blanching or whitening of the fingers. Symptoms include whiteness, tingling, numbness, muscle fatigue, a loss of grip and very often pain from white finger attacks.

Eliminating the cause of vibration or vibration exposure to the worker is the best way of preventing Vibration induced injury. Some ways of doing this may include using non-vibrating tools and machinery to perform the job. Substituting the tool for one with less or reduced vibration, is the next best step. More often than not however, both these options are unavailable.

Control measures

Safety professionals can however reduce the effects of vibration by implementing several alternative control measures. Engineering vibration reducing or dampening measures to reduce vibration exposure, or regular cleaning, maintenance and replacement of parts and tools to keep equipment and tools functioning smoothly with minimum jerks and jolts.

PPE like gloves provide a barrier between the source of the vibration and the worker, reducing the impact on the hands and arms.

Gloves like Ergodyne Proflex 9000 are certified to meet EN 388:2003/ANSI S3.40/ISO 10819-1996/EN420/ standards for anti-vibration, and in addition to reducing the effects of vibration, help loosen incorrect and tight gripping of tools; another factor contributing to HAVS.

Further to providing correct PPE, worker training about the long-term effects of vibration exposure and correct tool gripping practices, and tool vibration information can minimise the harmful effects of vibration.