Our client, a prominent manufacturer in the agricultural spraying equipment industry, faced challenges in welding a range of different sized repetitive parts. With a focus on increasing efficiency while maintaining the utilisation of their skilled welders, the client sought solutions to streamline their welding processes. They aimed to optimise their workforce by assigning skilled welders to more challenging tasks, while simultaneously enhancing productivity and consistency in welding repetitive parts.

KEY CHALLENGES

- Repetitive Parts: The manufacturing process involved numerous repetitive parts, leading to monotony and reduced efficiency in manual welding operations.

- High Volume Production: The demand for agricultural equipment necessitated high volume production, placing strain on existing welding resources, and limiting scalability.

- Optimising Skilled Labor: The client sought to maximise the utilisation of their skilled welders by assigning them to more complex welding tasks, requiring a solution to handle repetitive welding operations.

- To address the challenges of repetitive welding operations and increase overall efficiency in agricultural equipment manufacturing, our team proposed a comprehensive robotic welding solution tailored to the specific needs of the client.

SOLUTION HIGHLIGHTS

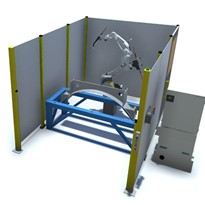

- Single Station Headstock: For larger parts requiring rotation to achieve optimal welding positions, a single station headstock was implemented. This allowed for precise rotation of the parts during welding, ensuring consistent weld quality across all positions. This system utilises the Fanuc ArcMate 120iD/12L Robot equipped with a Kemppi A7 welding system. The Fanuc ArcMate 120iD/12L robot provided high-performance welding capabilities for handling repetitive welding tasks efficiently and accurately.

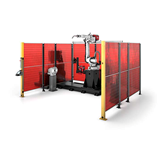

- Flexweld System: For smaller parts, a Flexweld system was deployed, utilising the easy-to-use Fanuc CRX robot in conjunction with the Kemppi A7 welding system. This versatile set-up enabled seamless integration into the production line and enhanced flexibility in welding various part sizes and configurations.

- Skilled Labour Multiplication: By integrating robotics into their welding operations, the client multiplied their skilled labour force, allowing skilled welders to focus on more challenging and intricate welding tasks while robotic systems handled repetitive operations with precision and consistency.

RESULTS

- Increased Efficiency: The implementation of robotic welding systems significantly increased efficiency in welding repetitive parts, reducing cycle times and maximising production output.

- Optimised Skilled Labour: Skilled welders were freed from repetitive tasks, allowing them to concentrate on more complex welding operations that required their expertise and craftsmanship.

- Consistent Weld Quality: With robotic systems handling repetitive welding tasks, the client achieved consistent weld quality across all parts, ensuring product reliability and customer satisfaction.

Our tailored robotic welding solution enabled our client in the agricultural equipment manufacturing industry to enhance efficiency, optimise skilled labour utilisation, and achieve consistent weld quality in high volume production. By leveraging robotics technology, we empowered our client to streamline their manufacturing processes and maintain competitiveness in the market while fostering a more rewarding work environment for their skilled workforce.

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)