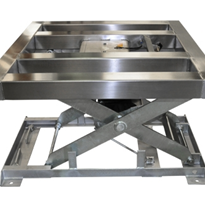

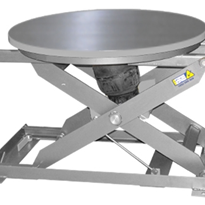

Our innovative pneumatic de-mount table is designed specifically for extracting concrete cylinder samples from 100mm thermal moulds.

How It Works: Our thermal moulds feature a small hole at the bottom center, allowing compressed air to be injected using a small air cleaning nozzle. This simple mechanism lifts the mould off the specimen with ease.

Key Features:

- User-Friendly Operation:

- Remove the lid from the thermal mould.

- Place the mould upside down in the pneumatic table nozzle.

- Pull the lever for extraction.

- The concrete sample is safely extracted into the table, ready for removal.

Specifications:

- Rigid Site Standard Attenuated Cabinet with an integrated air compressor.

- Pneumatic Extraction Mechanism with a nozzle head and positioning ring for easy operation.

- Heavy Duty Construction with crane lugs, fork pockets, and wheels for easy relocation.

- Secure Storage with adjustable shelves, dual-locking doors, and a powder-coated finish.

Compressor Features:

- 2.8L/Min 6 Bar adjustable, low-noise compressor.

- Oil-free Direct Drive motor for minimal maintenance.

- Dual cylinders with low RPM for reduced noise and power consumption.

- Rubber feet to absorb vibrations and noise.

Press Fixture Features:

- Rapid movement hand press with adjustable height.

- 25mm Diameter Steel Column for adjustable sealing head height.

- 240 V single phase, 10 amp power supply.

Hylec Controls' pneumatically controlled extraction jig is designed for the safe removal of concrete cylinders from plastic moulds. The mould is placed inverted over a recessed basket, and a customised rubber nozzle is fitted. A manually activated air switch controls the extraction under regulated air pressure.

Discover how Hylec Controls is setting new standards in concrete testing with this revolutionary technology.