To say the warehousing and logistics sector has been under pressure in recent years would be the understatement of the pandemic. Supply chain reliability has gone out the window, and here in Australia we’re incredibly exposed. Congested ports and lack of people power mean a typical container now spends 20% longer in transit than it did before the pandemic.

Sometimes even longer if you’re stuck in the Suez Canal...

Delays in the supply chain: we need people!

Everything is taking longer and many factors are out of our control. Anyone you speak to will have a story to share. Of how they’re still waiting on the uniforms for their kid’s soccer team even though they were ordered months ago. Or of how the new computer they wanted for Christmas didn’t arrive in time. Because we’d all gotten pretty used to having our orders fulfilled really quickly. And the average Joe or Jill wasn’t thinking too much about the cogs in the wheel needed to make it happen. Supply chain reliability is the new economic pandemic. And even with the introduction of automation, supply chains need people.

Without people power, everything grinds to a halt.

People Power

So, how can we keep our people happy? We know industrial disputes are increasing, and people are pushing for wage increases. Lower paid positions are becoming harder to fill. But for real wage increases to be sustainable, they need to be paired with increased productivity. We need our people working harder AND smarter.

And we need to keep our people safe. Because there’s a correlation between good working conditions and labour retention. Put simply, if we can provide a good working environment for our teams, they’re more likely to be productive and stay in the job.

Boosting Productivity. How?

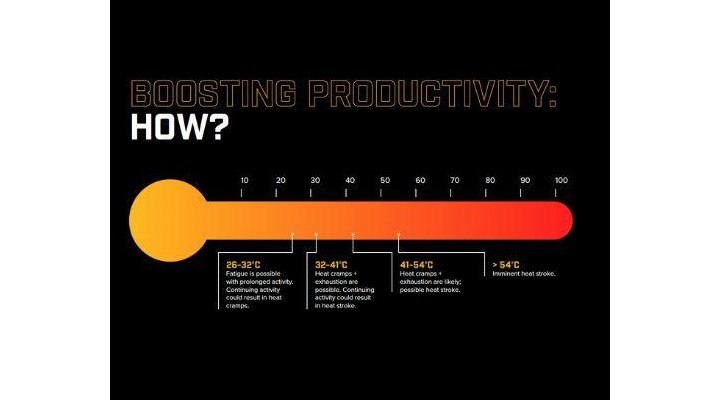

Obviously overheating and heat stress are major workplace safety concerns, but a study by Helsinki University of Technology in Finland found that even at temperatures above 25 degrees celsius, worker performance starts to decrease.

Productivity losses vary by climate zone, with warmer zones seeing larger losses, but on average, annual productivity losses decreased by 17% with the addition of elevated air speed (at 160 fpm (0.81 m/s). So we know fans can directly impact productivity. For every additional 1 degree celsius increase in temperature, you’ll lose another 2% in workers’ performance.

Anything above 32 degrees celsius and heat-related illness risk increases and safety concerns increase. And heat stress becomes a very real risk.

So, what do we mean by heat stress?

Strenuous activity that increases your metabolic rate will increase the amount of heat your body produces. And if you’re undertaking this activity in a hot environment, your body is less able to reject heat into its surrounds, and we can overheat.

So heat stress is the build-up of heat in our bodies to unhealthy levels, and in severe cases, it can lead to heat exhaustion and heatstroke. Sure a bit of heat, when you’re at the beach or relaxing in a sauna, is ok - you’re generally pretty stationary at those times.

But working in excessively hot temperatures can be extremely dangerous, and even fatal. For example, between 2005 and 2014, 13 workers died in Australia from being exposed to ‘environmental heat’.

As building operators and owners, we have an obligation to create a safe, comfortable indoor environment, especially in warehouses where thermal comfort is key to keeping workers safe and healthy.

Put a worker in a hot warehouse and expect them to maintain high levels of activity?

You’re in trouble.

Better working conditions = better outcomes

OK so we want our people to be working in a safe environment, and we know we’re likely to have a more productive team if we can keep temperatures lower. Because if temperatures are high, unions will also expect an increase in breaks for workers - the higher the temperature, the longer the downtime.

We recently worked with ASICS Oceania to install fans for temperature regulation in their warehouse.

After one of the hottest summers on record in NSW, ASICS was really concerned about low productivity and employee retention. The heat in the warehouse was causing people to leave.

But they wanted to be sure the downtime in installing the fans would be worth it, which is where our Computer Fluid Modeling Tool SpecLab came in.

We were able to model the impact of fans on their 25,000square metre distribution centre, accounting for their equipment, walls, forklifts and racking. So we knew before installation that the right fans would allow the workers to feel as though the temperature has dropped from 28 degrees to 25 degrees, increasing productivity by 8%.

After going ahead with the fan installation, ASICS has now seen an increase in pick rates of 5 units per hour during hotter months, equating to roughly $2000 per week of additional revenue. So they’ve paid off the fan installation costs in just 6 months.

Before the fans were installed most of our work was completed on motorised equipment so the staff were constantly moving and getting some type of airflow. When we installed our automation where staff would be in fixed positions we knew that we had to get something else to create that airflow, so due to getting the fans installed we never had any problems evolve due to the heat. - Andrew Carruthers, ASICS Oceania

How do fans help with temperature?

You might have guessed it - it’s time to talk in detail about fans. So how do fans form part of the solution to improving warehouse working conditions?

First of all, let’s look at the basics. Generally speaking, fans cool people, not rooms. The human body is constantly working to maintain its ideal temperature of around 36 degrees celsius, and sweating is one of the most effective ways we have of doing this.

As temperatures increase, the balance is harder to maintain, and when air becomes humid, it’s more difficult to regulate our temperature through evaporation of sweat from our skin. Fans help with this by creating airflow that evaporates perspiration from our skin, carrying away heat. The airflow also reduces the thickness of the hot, humid layer of air that builds up around our bodies, which improves heat dissipation.

In short, fans make our natural cooling mechanisms more efficient. So air movement reduces the likelihood of heat-related illnesses and accidents by making employees feel cooler and more comfortable.

-160x160-state_article-rel-cat.png)

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)