BS Australia has an extensive presence along the eastern seaboard, with a number of domestic and globally recognised brand names including AMH, King Island Beef, Royal, Swift Premium, Tasman Meats and Tasmanian Premium Beef.

Objectives

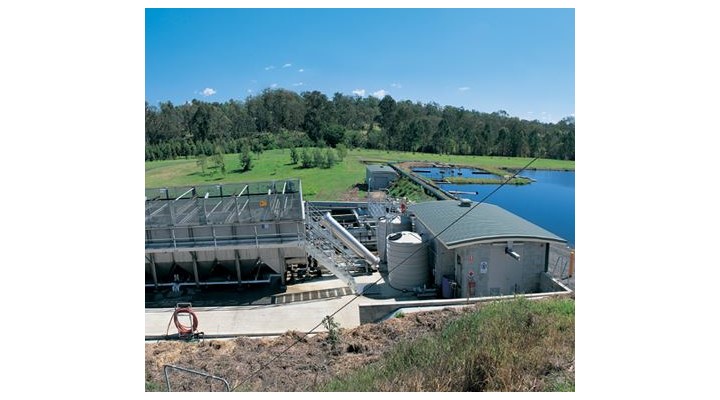

Wiley were contracted to design and construct a state-of-the-art waste water treatment facility at the JBS Australia plant at Dinmore.

The facility was to achieve the technological measures and performance criteria developed by JBS Australia and the Environmental Protection Agency to help JBS Australia improve the local Bremer River and to produce ‘A' class non-potable water, the standard of effluent for primary contact (such as swimming) or for direct use on market garden fruits and vegetables.

This project was an outcome of JBS Australia's membership of the Healthy Waterways partnership, a joint government, industry and community initiative to improve the health of South-East Queensland waterways.

Challenges

Achieving the performance criteria set by JBS Australia and the Environmental Protection Agency

Maintaining continuous operation of the JBS Australia plant and the final treatment process during construction of the new facility

Designing the facility to:

- house the waste water system, which incorporates a system for dosing alum to reduce its phosphate level, a tertiary dissolved air flotation (DAF) system which takes suction from the final pond to reduce suspended solids, a chlorine contact tank to disinfect the effluent, and aerators to ensure sufficient oxygen in the discharge

- have minimal visual impact, to be attractive and to match the curved roof style of the main plant since the equipment is housed near an environmentally sensitive area adjoining the river

- ensure the system's 24-hour-a-day operation causes minimal disturbance and does not add to the overall noise climate of the area

- enable safe operation and maintenance.

Solutions

Advice

Coordination of preliminary design and budgets in conjunction with JBS Australia and the environmental consultant.

Design

Detailed design of the facility, which encloses the DAF equipment and standby diesel generator in a soundproof pump house, and features access platforms and lifting provisions and space for mobile cranes and transport equipment for the removal of plant items when required

Development of specifications for civil works.

Engineering

Direct procurement of waste water treatment equipment and coordination with civil construction.

Construction

- Tendering, contracting and supervision of all civil work, such as construction of access roads.

- Management of the installation and connection of the process plant in tandem with civil works.

Results

Wiley delivered a state-of-the-art waste water treatment facility, which meets its performance criteria and enables JBS Australia to recycle or reuse on site, or release to the Bremer River, all water from its meat processing plant.

The facility was commissioned ahead of schedule and within budget and demonstrates JBS Australia's ongoing commitment to the environment.