For producing stainless steel containers, switch cabinets or stainless steel furniture usually panels with a so-called industrial finish are used. The production process involves welding, bending,

drilling, etc. Scratches can therefore be hardly avoided, and these then have to be removed.

Remove scratches, weld seams in 3 easy steps

Step 1 - Coarse Grinding to removing scratches with ceramic or zirconium sleeve on expansion roller.

Removal of light scratches with POLY-PTX® zirconium sleeve K80. In the case of very deep scratches on stainless steel we recommend the ceramic sleeve grit 60. Tig welds can be removed using the rubber expanding roller with the POLY PTX pure zirconium sleeve or the ceramic sleeve.

Larger welding seams need to be flattened in advance with flap disks.

Step 2 - Intermediate grinding After the treatment with the zirconium sleeve the surface could be treated with the SC fleece sleeve on expansion roller. In the next working step the POLY-PTX® SC fleece sleeve (grit size: medium) is used for smoothing the surface roughened by the zirconium sleeve.

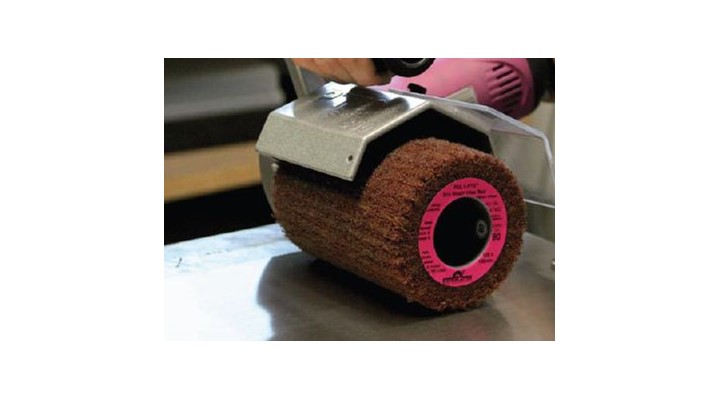

Step 3 - Smoothing - The entire surface is reworked through "oscillation" with the POLY-PTX® fleece wheel (grit 80 or finer, we have the largest range of SC fleece wheels from grit 60 up to 900). Oscillation technique: Through short forward and backward movements in a longitudinal direction and at the same time shifting to the side you achieve seamless, decorative surfaces (industrial finish).

Do you have a tip for our application guide? Have you gained interesting experience with our machines and

tools, which you would like to share with other artisans? Then write to us: the most interesting application tips will be published in our “Professional Guides” and in our customer magazine and will be rewarded with accessories for your applications.