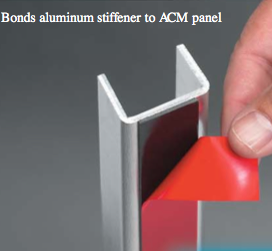

There are many brands of Architectural Composite Panels in Australia. Some of these Composite Panel Brands include Alucobond, Alucopanel, Alpolic, Symonite,Vitrabond, Alupanel, Di-Bond, Alucore & Alutri. High Bond Double Sided Tape such as the 3M range of Very High Bond - VHB Tapes are ideal for Composite Panel Instalation.

The two main 3M VHB Tapes recomended for Facade Panel/Composite Panel Instalation is the 3M 4941 VHB (Grey in Colour, 1.1mm thick) & the 3M 4991 VHB (Grey in Colour, 2.3mm thick) which are UV resistant & can be used indoors ( Wall Cladding, Ceilings, Curtain Wall Panels ) & outdoors (Facade/ Composite Panel Instalation, Cladding & Column Cover).

Using a Double Sided VHB Tape is a very efficient way of installing Aluminium Composite Panels.Using VHB Tape elimates having to use mechanical fasteners (screws,rivots,welds) making a smooth clean appearance aswell as reducing labour costs.

When installing Composite Panels, it is very important to know that Aluminium Composite Panel instalation must make sure that 55 square centimetres of VHB tape per kilogram must be used to support a static dead load. If these panels are being used externally, you must also factor in the wind load.

Below is the 3M recomended guide for bonding Composite Panels / Architectural Metal Panels

1. Adhesion & Surface Preparation

Adhesion is the molecular force of attraction between unlike materials, similar to a magnetic force. The strength of attraction is determined by the cleanliness & surface energy of the material. Metals surfaces such as aluminium and galvanised steel are generally considered to be a high energy surface. However, surface coatings such as paints & primers can change the surface energy of the metal. Likewise, coatings or paint on metal frames will also change the surface energy of a normally high energy surface like bare aluminium.

2. Tape width for Structural integrity - Dynamic load resistance from lateral wind forces

The width of tape must be the appropriate size to allow the wind load on the composite panel to be transferred to the building structure.

For dynamic tensile or shear loads (such as wind loads), a design strength of 85 kPa is used for VHB Tape. This design strength guideline provides a safety factor of at least 5 and was established based on material property testing as well as ASTM dynamic load testing for curtain wall applications. Years of real-life application success also supports the use of this design guideline for this application.

Perimeter bonded panels

The Trapezoid Rule is the industry established calculation used for determining the appropriate bonding agent width for a panel bonding application. This calculation is commonly used to determine “structural bite” for structural adhesive bonding applications and is also applicable for VHB panel bonding applications. Essentially it calculates the maximum load on the panel which occurs at area "Y", and returns the minimum tape required to comfortably handle the load:

Tape Width required (mm) = 0.5 x panel short edge length (mm) x wind load

(kPa)Tape design strength (85 kPa)

Example: 1200 x 2400 mm panel, perimeter bonded, with wind-load of 2.0 kPa

Tape Width (mm) = 0.5 x 1200 mm x 2.0 kPa = 14.1 mm - round up 16 m

85 kPa

Note: Always round up to the nearest whole number divisible by 2 and never round down.

Non-perimeter bonded panels

For panels bonded to the sub frame with intermediate supports, the total bond area (width of tape x length) must be at least as much as that calculated for a perimeter bonded panel.

Tape width (mm) 0.5 x panel short edge length (mm) x wind load (kPa) x actual bond length

Tape design strength (85 kPa) perimeter (mm)

Example : if the above panel was supported at 600 mm spacing by 5 x 1200 mm vertical lengths of VHB tape,then the width required is given as :

Tape widtn ( mm) 0.5 x 1200 (mm) x 2.0 (kPa) x 5 x 1200 mm

(85 kPa) 1200 x 2 + 2400 x 2 mm

= 21 mm x (7600 / 6000) = 16.9 round up to 18 mm.

3.Tape width for permanent loads – dead load holding

Panel bonding applications utilising unsupported panels require a static load calculation to determine the appropriate width of VHB™ Tape. A design strength guideline of 1.7 kPa should be used for static load calculations. This means that 55 sq. cm per 1 kg should be used to support static loads. The following static load calculation is used to determine the appropriate tape width for perimeter bonded panels.

Tape Area (sq cm) = 55 sq cm per kg x weight of panel ( kg)

Tape width (cm) = Tape area / total tape length

Example: 1200 mm x 2400mm, 4 mm thick composite panel with a weight of 16 kg, bonded by 5 x 1200mm (120 cm) vertical lengths of VHB tape

Tape Area req’d(sq cm) = 55 sq cm per kg x 16 kg

= 880 sq cm

Tape width (cm) = 880 sq cm / ( 5 x 120 cm)

= 1.47 cm

Tape width ( mm) = 14.7 mm - Round up to the nearest mm divisible by 2

= 16mm

Important; Both Dynamic load & static load calculations should be done. Whichever calculation results in the wider tape, is the width of tape you should use.

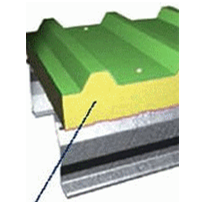

4. Tape thickness & provision for movement – thermal cycling, thermal expansion/contraction, deformations in building frame, settling of building over time

VHB Tape performs well in applications where two bonded surfaces experience movement relative to each other as a result of thermal expansion and contraction. VHB Tape can tolerate shear movement up to 3 times its original thickness (300 per cent shear strain). This means the

2.3 mm thick VHB Tape can safely experience shear strain up to 6.9 mm for short periods of time –such as the daily expansion and contraction due to solar heating. The façade or curtain wall system designer should calculate the amount of joint movement possible due to differential thermal expansion between the panel and metal frame and determine if this will result in less than 300 per cent shear strain on the

VHB Panel bonding Tape.

As an example, common aluminium composite panels can reach temperatures as high at 85ºC, resulting in as much as 1mm growth in each corner, per square metre of panel.

Panels should not have the corners or edges constrained by mechanical fixing that may result in buckling or deformation of the panel away from the plane of the panel. When the ends of panels are constrained in this way, the resultant bowing out of the panels from solar heating can cause excessive strain on the VHB tape.

Other sources of movement in the panel system, such as building settling, slab deflection, mismatch during assembly, should also be considered by the architect/curtain wall designer to verify that they are within the design limit of 300 per cent Short Term shear strain.

Other Design Considerations - Material Considerations

The shape of panel should be pre-positioned to measure/observe and significant mismatches. Where metal sections are abutted there is the possibility of mismatch. This can be caused by misalignment or by welded joints not being sanded. Ensure all mismatch is corrected.

With frameworks that have a flange, there should be sufficient space around the panel to allow for thermal expansion. Do not force the panel into frame when aligning, since a permanent strain on the bond would be induced due to the spring back of the metal panel. In this case, the frame & panel fit must be corrected before bonding.

NEVER "double up" VHB tape in order to create a thicker tape account for surface mismatch.

5.Tape Application Methods

The Work Environment

It is important to establish an appropriate work area before assembly of VHB bonded panels. The workplace should be free from excessive dust, dirt and other airborne contaminants. The VHB Tape will bond strongly to the surface it contacts. Should this be a layer of dust, dirt, grease, oils, etc., then an inadequate bond will be made to the component surface.

The workplace should be at a minimum temperature of 15°C.VHB Tape should be conditioned at 15°C minimum (or > 0°C if working with VHB 4951). VHB Tape is a viscoelastic adhesive, which forms a bond by "wetting" (making intimate contact with) the surfaces to which it is applied. When temperatures are low, this wetting process is slower, and it takes more time to reach full bond strength with 100 per cent wet-out of the surface.

If the temperature of the VHB Tape roll or the components is below 15°C, then the initial wetting may be so low that full bond strength may not develop before the panel is erected, and therefore put under load. Similarly, once the initial bond is made, then the 15°C minimum is still required, so that the adhesive can continue to flow until full bond strength is achieved. This is usually achieved when the fabricated panels are held overnight at the minimum 15°C condition.

Surface Preparation

Proper surface preparation is the critical first step in the installation process. Proper preparation of a surface prior to the application of a pressure sensitive tape is a key factor in ensuring maximum bond strengths. Contaminants act as a barrier between the adhesive and substrate.

Even a fingerprint on an otherwise clean surface may impair adhesion.

Care must also be taken to examine surfaces for moisture, particularly during periods of high humidity as it is possible for an invisible film of water to be present. After surface preparation has been completed, the VHB tape should be applied within 5-10 minutes to avoid contamination or oxidation of abraded metals.

Bonding Procedure

Tape Application to Sub-frame Members and Pressure Application: The tape should be handled at the edges or by the protective liner with effort made to avoid contact with the exposed and tacky bonding surface. Excessive contact with the bonding surface may contaminate the tape and reduce bonding performance.

Apply the tape to the prepared surface aligned with the edge starting in one end working down the entire length of the metal extrusion. It’s best to apply light pressure to the tape as its making first contact with the surface to avoid air entrapment (bubbles) between the tape and the metal.

A hand held roller, squeegee or even fingers may be used for this step. After applying the tape, be sure to apply pressure to the tape with a squeegee or rubber roller to ensure proper surface contact. Once the tape is applied to the sub-frame, the panel should be installed within 1 week, as the VHB liner has a limited life in exposed environments.

Panel Installation

Once the panel is in the correct alignment, the panel is pushed onto to tape to make contact with the exposed, tacky tape surface. Once the panel is bonded to the frame, final application pressure must be applied around the ALL of bond area of the panel. It is insufficient to push the panel by hand. A hand held roller can be used to apply roll down pressure of at least 15psi (1kg/cm2). To achieve 15psi pressure on the tape, as much as 20kg rolling force may be required.

Weather Sealant Application

A neutral-curing (non-acidic) silicone sealant should be applied around the entire perimeter of the panel once it’s bonded to the panel bonding frame. This will act as a weather sealant and help to protect the VHB Tape from potentially aggressive cleaning agents. Sealant may be applied immediately after final the pressure application to the assembled units. Use an appropriate sealant that has the required performance and durability for the application.

Important: When using Silicone or Polyurethane sealants, be careful to avoid contaminating other prebonded parts or works areas where VHB Tapes will be applied.

Bond Build Rate

After proper application of the tape as described above, the bond strength will increase as the adhesive flows onto the surface making more intimate contact, with full strength being achieved within 72 hours. However, with the correct amount of tape , surface preparation and application pressure & temperature, the tape will support the panel immediately – there is no need for any supplementary clamping.

-160x160-state_article-rel-cat.png)