The latest strand jacks involve computerised synchronisation of lifts involving multiple hydraulic cylinders handling loads of hundreds and thousands of tons.

Enerpac HSL Series strand jacks – in individual capacities from 34-1405 tons – are being matched with a sophisticated SCC Smart Cylinder Control System software program that synchronizes the motion of the strand jacks and adjusts the motion to the loads per lifting point.

Enerpac Australasia Heavy Lifting Technology Manager, Warren Baltineshter, says the SCC program enhances the value of a proven heavy lifting technology that has demonstrated considerable worth on major Australasian construction, infrastructure projects and resources, where it has provided synchronous control of heavy lifting capacity within an economical and compact footprint.

The Enerpac strand jacking system – which has been employed within Australasia on lifting 12 mining ball mills weighing up to 1400 tons each, for example – is ideal for precision heavy lift projects such as bridge lifting, mining, oil and gas plant and rigs, silo maintenance and materials handling plant. (www.youtube.com/watch?v=F13LkNx31OQ)

Each HSL system is supplied with the SCC hardware and software package as standard. The SCC system not only monitors progress, it controls the operation within safe working limits specific to the particular job and client demands.

"For example, the system governs maximum permissible load and synchronous position at each lifting position and between them, which are key parameters that the SCC uses to precisely manage the lifting operation," says Baltineshter.

Powered either by electrical or diesel-driven hydraulic power packs, the HSL system features:

- Control by a single operator from a central location for increased safety.

- Automatic locking/unlocking operation for optimum load control and load holding.

- Telescopic nickel-plated strand guide pipes to prevent bird-caging (in which wire rope strands are untwisted and spread outward) enhancing smooth and reliable operation.

- Anti-corrosion Lunac coating of internal components for aggressive and marine environments. Corrosion-treated high endurance wedges.

- Long strokes from 25 – 58cm within compact high-pressure cylinders (up to 5,000psi).

- Lifting anchors included with each cylinder for convenient mounting and safety

- Lloyds witness tested to 125 per cent of maximum working load

Baltineshter says strand jacking offers compact high capacity lifting capabilities that are easy to deploy, compared with mobile and crawler cranes. The technology offers a high lifting height, with true vertical lift and no drift.

"Strand jacks are recognised today as one of the most sophisticated, safe and precise heavy lifting systems, used to lift and lower loads where the use of conventional cranes is neither economical nor practical. SCC control advances the technology even further in this regard.

"The global Enerpac organisation continually improves the reliability, durability, safety and control of its strand jacks, making them an industry standard for heavy lifting in Australasia and worldwide."

How strand lifting operates

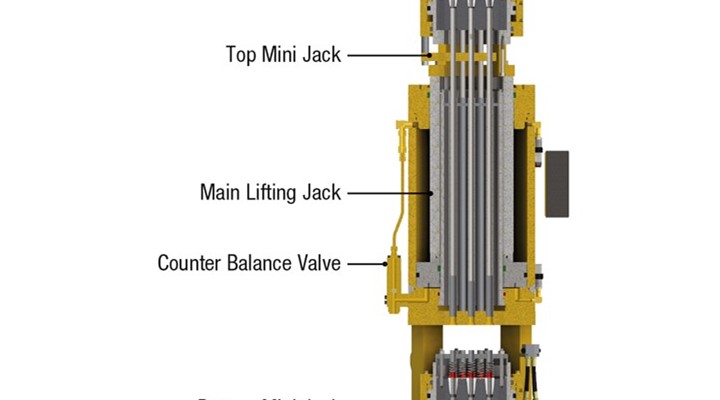

A strand jack can be considered to be a type of linear winch. In a strand jack, a bundle of steel strands passes through a main hydraulic cylinder, which acts as the lifting or lowering jack. The strands in the HSL are either 15.7mm or 18mm diameter each, with multiple strands supporting the load.

Above and below the main hydraulic cylinder are mini jacks with anchor systems of wedges that grip the strand bundle when the load is being lifted or lowered.

Lifting and lowering a load is achieved by hydraulically controlling the main jack and both mini jacks alternately, feeding the strands through the cylinders in steps equivalent to the cylinders' strokes (which range from 25 to 58cm).

The wedges close automatically to lock the suspended load in place if the hydraulic system loses pressure, further ensuring safety.

Strand jacks are an integral member of a broader Enerpac family of heavy lifting technologies (including synchronous and crane-suspended types), all of which are engineered to increase the safety, precision and cost-efficiency of heavy lifts.