The exact equipment needed may vary depending on the specific hazards and characteristics of the confined space, but here are some common examples of equipment used in confined space work:

1. Gas Detectors/Monitors: Confined spaces can be prone to hazardous atmospheres, such as the presence of toxic gases, oxygen deficiency, or flammable substances. Gas detectors or monitors are essential for continuously monitoring the air quality within the confined space. They can alert workers to the presence of dangerous gases and help prevent exposure.

2. Ventilation Equipment: Ventilation is critical to control air quality and maintain a safe working environment in confined spaces. Equipment like blowers, fans, or ducting systems can be used to provide adequate air circulation, remove contaminants, and ensure sufficient oxygen levels.

3. Lighting Equipment: Confined spaces often have limited natural light or may be completely dark. Adequate lighting is crucial for visibility and safe operations. Portable lighting options, such as intrinsically safe and explosion-proof lights, are commonly used to illuminate the workspace effectively.

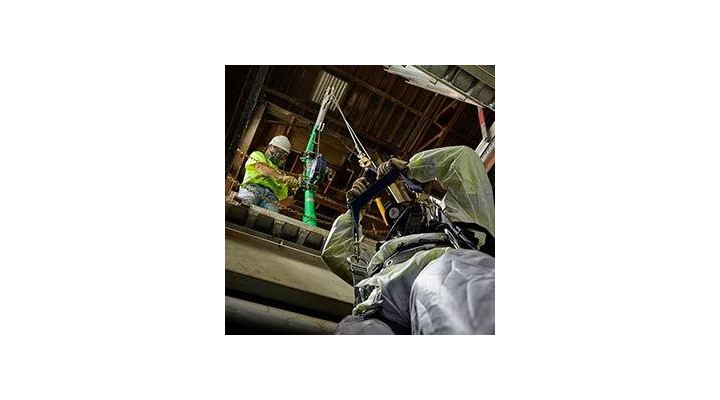

4. Safety Harnesses and Fall Protection Equipment: If there is a risk of falling in the confined space, such as vertical entry or work near unprotected edges, appropriate fall protection equipment is necessary. This includes safety harnesses, lanyards, self-retracting lifelines, and anchor points to secure workers and prevent falls.

5. Communication Devices: Communication is vital when working in confined spaces to maintain contact with workers inside and outside the space. Equipment like two-way radios, intrinsically safe communication devices, or hand signals may be used to facilitate communication and ensure effective coordination and emergency response.

6. Personal Protective Equipment (PPE): Depending on the specific hazards present in the confined space, additional PPE may be required. This can include protective clothing, gloves, eye protection, respiratory protection, hearing protection, and other specialized equipment based on the identified risks.

It's important to note that confined space work should be approached with proper training, procedures, and risk assessments. The equipment needs to be selected based on a thorough evaluation of the confined space and the potential hazards involved. Adhering to relevant safety regulations, guidelines, and industry best practices is essential to ensure the safety and well-being of workers in confined spaces.