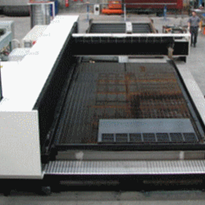

In the dynamic world of laser technology, we proudly introduce an outstanding integration that promises to elevate your marking and engraving capabilities to unparalleled heights. The U300 Galvo laser marker, renowned for its precision and lightning-fast speed, meets the simplicity of our advanced laser software Ruby®. This combination amplifies the U300’s capabilities and ushers in a new era of efficient and seamless laser operations. In this article, we will have a closer look at the U300 and how the pairing with Ruby® can benefit your workflow, productivity, and flexibility.

Little space, big impact.

The U300, designed and manufactured in Austria, is a galvo laser system characterized by high-speed performance, making it the ideal choice for individual pieces and small batch production. The U300’s compact footprint ensures that little space is needed for maximum functionality, allowing you to seamlessly incorporate it into your workflow. With this space-saving design featuring a marking area of up to 190 x 190 mm, it caters to diverse industries, including promotional product companies, engravers specializing in personalization, and manufacturing.

Flexible and optimised workflow.

The integration of Ruby® with the U300 laser marker opens up new possibilities for businesses seeking enhanced productivity and application flexibility. The high focus tolerance of a U300 offers exceptional flexibility for versatile applications even on uneven products, whether the component is round, or the surface is corrugated.

With our Ruby® laser software, your team can work in parallel workflows. This means that your team can seamlessly divide tasks and operate on multiple stages of your laser projects simultaneously. While one team member focuses on designing and preparing laser jobs in Ruby®, another can operate the U300 on-site. This streamlined process ensures different orders can be handled at the same time without disrupting ongoing laser processes. The ability to manage multiple facets of laser jobs concurrently empowers your team to meet tighter deadlines and handle a higher volume of projects with precision.

Ultimately, our Ruby® laser software facilitates a synchronised and efficient working environment, translating into improved output and resulting customer satisfaction.

-205x205.jpg)

(1)-205x205.jpg)