Imagine having a stringent process of producing sanitised food packaging only for it to be contaminated during transit. Aside from financial loss, there are bigger risks involved such as public health safety. Such complications is one of the biggest reasons why semi-automatic strapping machines and other equipment play an important role to prevent such incidents.

Most of us are concerned with the cleanliness of food factories that other parts of food processing are overlooked such as food packaging.

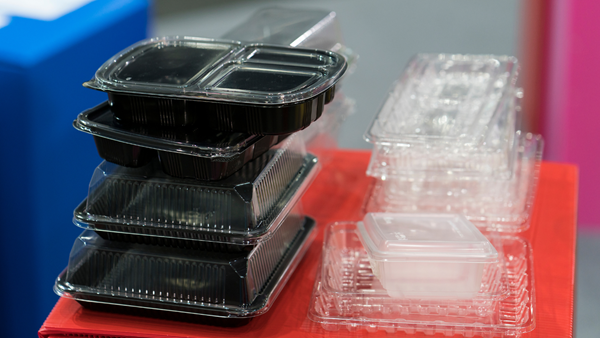

The food packaging industry is one of the booming industries today due to the rise of the food delivery market. It follows strict regulations since it is a material where food contamination can occur or spread. To ensure a sterile environment, most companies often rely on contactless processes.

Small to medium food packaging businesses, on the other hand, are not yet fully contactless. However, with the help of equipment like strapping machines and conveyor belts, they can start to slowly automate and reduce the risks of contamination.

How packaging or strapping equipment secures high-risk products like food packaging

In a time where people are more conscious about the chemicals in their food, as a business, the last thing you want is to get cancelled for any contamination. There are three types of contamination in food packaging businesses that can affect their food-safe status:

- Physical contamination: This type of contamination is also known as Dirty Dozen and includes the following contaminants:

- Metal

- Wood

- Insects

- Foreign objects like jewellery

- Needles

- Bone

- Insects, etc.

- Chemical contamination: Two classifications of chemical contaminations are the inclusion of inappropriate chemicals in packaging and excess amounts of chemicals that disqualify the food packaging as food-safe.

- Microbiological contamination: Mould, disease-causing bacteria, fungus, and strains of yeast are the common types of contaminants in this category. It’s the most critical type of contamination because of its big implications on food safety, brand reputation, supply chain disruption and loss due to contaminated products considered as waste.

Any contamination may occur from manufacturing, transportation, storage, and retail of food packaging products. Each type of contamination is categorised into three based on their possible source, such as:

- Natural

- Man-made or human-made

- Human-introduced contaminants

Based on those factors, food packaging businesses manage a lot of risks that’s why it heavily relies on equipment to maintain sanitation and compliance to regulations. Without proper management, here’s what’s at stake on a single incident of contamination for a food packaging business:

- Risks the public health which can cost lives

- Financial losses due to product recalls and crisis management efforts

- Disruption in supply chain operations

- Brand reputation damage

- Public scrutiny and a regulatory or compliance costs

- Increased risk of having revoked permits

- Ripple effect on both ends of the supply chain

- Downstream Impact: Retailers, food manufacturers, and restaurants that rely on affected packaging materials will be affected by the product recalls and endure service disruptions that can affect their customer satisfaction and business continuity.

- Upstream Impact: Raw material suppliers may need to adjust their schedule for the additional production and distribution to replenish the recalled products.

The importance of a no-contact production line and big impact of contamination risks highlights the value of equipment like conveyor belts, automation, and contactless packaging for businesses.

The sensitivity of specialised food packaging

Some foods require specialised materials using expensive packaging materials. The stakes are even higher in manufacturing packaging for high-risk or highly sensitive products, such as perishable goods and foods that are sensitive to temperature fluctuations.

With varying sizes, sensitivity and forms of food packaging, the combination of manual effort and automated features of semi-automatic strapping machine makes it a perfect equipment for small to medium businesses.

The manual adjustment involved in semi-automatic strapping machines helps secure the form of food packaging products and ensures that customers receive them in pristine condition.

6 Considerations in Protecting Food Packaging Products

Oftentimes, food packaging business owners know the whole process of the business but overlook some steps that hold hidden opportunities for cost-savings, process efficiency, and bottlenecks for scaling. These include:

- Temperature Protection: Some types of packaging are sensitive to certain weather conditions that can damage their form such as paper products. They should be kept in a dry place and away from humidity and contaminants like mould.

- Stackability and Denesting: Packaging should be designed for efficient storage and transport because every space can mean cost. For example, proper stacking methods help businesses transport a standard number of boxes per truck.

- Storage Conditions: Proper storage is vital for preserving the integrity of food products. As a food packaging business, the goal is to build products that are durable enough to withstand long-term storage and retain their pristine and food-safe nature.

- Strapping: The strapping process may be a simple step but it is crucial for securing packaged goods, particularly during transportation and managing spaces in storage.

- Transportation: Packaging materials and straps must be secure enough to endure every bump or squeeze during transport. This includes protection against moisture or other potential hazards that could compromise the safety of the food to be inserted on the packaging.

- Sanitation: Equipment used in food packaging should be easy to clean and sanitise to prevent contamination.

Reevaluating these factors help business owners ensure that their food packaging processes are optimised for both security and sanitation which ultimately protects their products, customers, and their brands..

.png)

How semi-automatic strapping machines helps with quality control and security for food packaging business

Semi-automatic strapping machines play a pivotal role in ensuring the order and form of food packaging from the manufacturing plant to the customers. These machines offer several advantages that make them an essential tool for businesses in the food packaging industry providing a variety of food-safe products.

Enhanced Quality Control

Semi-automatic strapping machines use cutting-edge technology to ensure that each package is securely strapped using consistent tension regardless of whether they have simple or complex designs. This prevents packages from opening or shifting during transit, which could lead to contamination or damage.

Customisable Solutions and Versatility

Businesses can tailor their packaging solutions to meet specific business needs which semi-automatic strapping machines can flexibly accommodate like different packaging designs and sizes for various product types.

Compliance with Food Safety Protocols

Using a semi-automatic strapping machine helps businesses qualify for food safety certifications by ensuring that the packaging process has less human contact and meets industry standards. This is particularly important for the food packaging industry that needs to comply with strict regulations regarding food safety and hygiene.

Efficiency and Cost-Effectiveness

Semi-automatic machines are more affordable than automatic strapping machines so there are reduced overhead costs. They are designed to be efficient, reducing the time, labour, and physical effort required for the strapping process.

Durability and Reliability

Semi-automatic strapping machines are built to last, with durable components that can withstand continuous use that goes beyond human strength thresholds. Their reliability ensures that businesses can maintain a consistent packaging process without interruptions.

Take the Next Step in Securing Your Food Packaging Products with IndustrySearch

With the rapid growth of the food packaging industry, ensuring the safety and quality of your packaging products is non-negotiable. Don't give any type of contamination, damage, or inefficiency a chance to hinder your growth as a business.

Invest in equipment that will help protect your products, streamline your operations, and keep your customers satisfied. With IndustrySearch, sourcing the best semi-automatic strapping machine in Australia is just a few clicks away.

In partnership with verified suppliers, get a smoother procurement process and get a comprehensive quote for all your industrial needs today.