Very Small Particle Company Pty Ltd has come a long way in a short time.

The Brisbane-based company began operating in 1999, undertaking research and development into metal-oxide particle production techniques.

With the help of a $250,000 Australian Government innovation grant from AusIndustry in 2000, the company has developed a process for producing a wide range of advanced metal oxides with enhanced properties.

These oxides are used in a range of applications, including fuel cells, batteries, electronics, and as catalysts.

The technology was a breakthrough in the manufacture of complex metal oxides and allowed five or more different elements to be combined at a nano-crystalline level.

When complex metal oxides are prepared as nano-materials with near-atomic scale features, their physical, electrical, magnetic, optical and mechanical properties are enhanced.

And Very Small Particle Company’s latest project – a prototype production plant designed to produce nano-materials in bulk – is attracting interest overseas, particularly in Europe and theUnited States.

The project began in late 2002, was completed in mid 2004, and was also supported by a $1.4 million AusIndustry innovation grant.

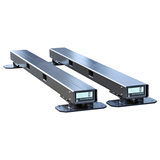

The prototype plant has a production capacity of about 60 tonnes per year and is undergoing commissioning, with the technology forming a basis for future industrial-scale plants.

Company director, Dr Peter Talbot, said the project built on technology developed with its first AusIndustry grant.

It involved the design of a reactor that has been progressively scaled up from the laboratory bench to one producing several kilograms per day. It is now industrial-scale as a result of some innovative manufacturing processes.

“The completion of the semi-continuous prototype plant allows us to produce complex nano-scale compounds through a method that is cheap,” Dr Talbot said.

“At the same time, it produces particles that have high surface area and controlled porosity – attributes that are very important for the target applications of fuel cells, batteries, electronics, and vehicle emission.

“International patents have now been awarded for the process, which is considered superior to other processes.”

Dr Talbot said the process was based on preserving optimum atomic-scale (OAS) mixing achieved in solutions of metallic ions.

“The OAS-mix and distribution is then maintained through controlled heating reactions that result in a dry powder product. The powder is milled and classified to customer requirements,” he said.

While markets for complex nano-scale metal oxide powders are increasing, the development of many end-user technologies was being held back by the inability of industry to supply large quantities with consistently high quality at a commercially acceptable price.

Unlike many other nanotechnology companies, Dr Talbot said Very Small Particle Company’s manufacturing process has been designed to meet the demands of large-scale industry.

This has provided the capacity to offer a wide range of advanced metal oxides to customers throughout the world.

The company has also applied its versatile process to fast-track development of nanometre-scale environmental catalysts.

Its scientists have found that when these catalysts are made with nano-scale grains it significantly enhances efficiency.

The catalysts efficiently remove toxic gases from vehicle exhaust using fewer platinum-group metals – equating to about one third of the quantity required by conventional three-way catalysts.

Very Small Particle Company ’s innovative research and development towards creating an industrial-scale manufacturing process has placed it well to exploit lucrative worldwide metal-oxide markets.

Its nanotechnology has great potential to generate global business opportunities, worldwide environmental benefits, and recognition for Australia in environmental management.