The Customer

Calpine corporation is one of the largest geothermal and natural gas power plant businesses in the United States with an emphasis on efficiency and environmental responsibility. Calpine is creating power for millions of homes from numerous operations throughout the U.S.. Including the incredibly clean and massive geothermal power plant located in Sonoma County, Northern California at The Geysers. Encompassing a geothermal power plant and associated steam fields, the Sonoma Operation has become the largest source of renewable geothermal power for America since its construction in 1983.

Customer Challenge

The Sonoma plant is a community-based station, so if there were any issues to arise it could easily result in power failure for some homes, if not more. Calpine needed appropriate failsafe plans and measures to prevent such disaster from occurring.

It is not uncommon for an instrument such as the valve positioner to briefly lose signal at geothermal power plants, such as the one in Sonoma. However, regular valve positioners tend to ramp up or down to either 100% or 0% in the event of this signal failure, which can cause problems for the plant or even the homes dependant on the plant.

Product Solution

In need of a very particular valve positioner, Calpine quickly turned to Innovec Controls for their reliable reputation of high value custom made electronic instruments.

The VP100D valve positioner was a ready available product by Innovec, however it was modified for Calpine, to stop in the event of signal failure.

Results Achieved

The modified VP100 for Calpine allowed them to maintain a higher level of safety and production without the risk of signal loss hindering their production process. Innovec has been supplying the VP100D Valve positioner to Calpine’s Sonoma Operation for 5+ years and continues to do so today.

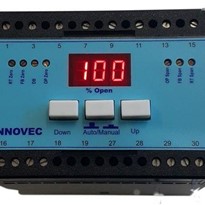

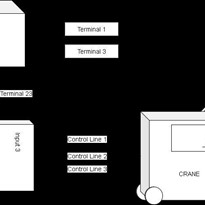

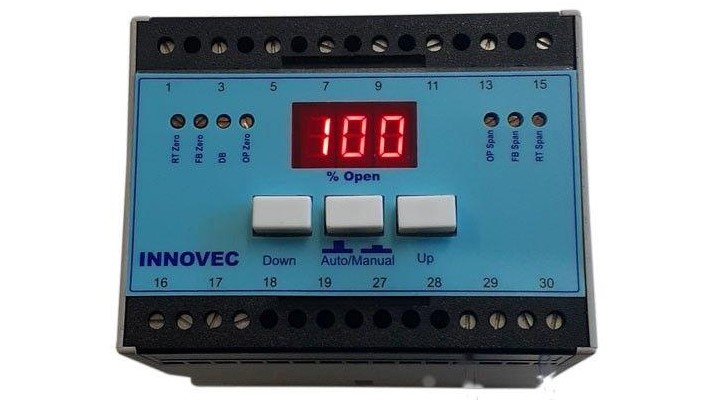

VP100D - Valve Positioner

The VP100 Valve Positioner is an electronic valve positioner which operates within the motor feedback circuit. It has a feedback signal of 100 to 10,000 Ohms and generates 2 independent relay contacts (ramp up/ramp down) and drives a 3 digit LED display showing valve position in percent open. The instrument operates in auto mode where it tracks the input signal or in manual mode where the actuator can be driven to any desired position.

Key Features

- Auto/manual control

- Manual ramp up and ramp down

- 115 or 240 VAC 47 - 63 Hz supply

- High contrast 10mm LED display

- Din rail mount enclosure

- Isolated 4 - 20mA retransmission

About Innovec

For over 25 years Innovec controls has been a specialist provider of process control instruments and electronics for the food and engineering industries. Supplying to some of Australia's Major food and industrial businesses and government contracts through a network of engineering wholesalers and suppliers.

Innovec is an ISO 9001:2015 certified business

-720x400.jpg)

-160x160-state_article-rel-cat.png)