The conventional way of doing this is to heat the outer housing with a flame to allow the bearing to fit.

An alternative method has been to use liquid nitrogen to freeze and shrink the component prior to fitting. On remote mine sites, this is often expensive and inconvenient as the liquid nitrogen often has to be shipped from capital cities which is expensive and time consuming.

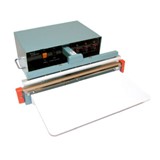

Another alternative method is to use a two-stage water-cooled industrial freezer which is capable of freezing the item to -70°C, or with the use of liquid nitrogen boost down to -180°C. Pre-cooling the item in a freezer minimises the use of liquid nitrogen – and in most cases nitrogen boost is not required. These chambers are normally installed in a workshop and the part must be brought to the workshop for fitting, which is often not feasible.

The freezer manufacturer has now developed a ruggedized industrial freezer which is connected to an air-cooled water chiller which can all be skid-mounted on the back of a truck and taken to the site where the item needs to be fitted. The air-cooled water chiller eliminates the need of a suitable mineral-free water supply which is often not available on site. This can operate up to ambience up to +55°C.

If the chiller is used in a workshop environment and used continuously it is possible to speed up the chilling process by filling the chamber with delaminate, a natural liquid that freezes at about -90°C. This allows the part to be cooled much faster than if air-cooled with the freezer. Other metallurgical applications with steel include age hardening, stress relieving, martensiting, and dimensional stabilisation.

Hylec Controls is CSZ Industrial agent in Australia and New Zealand and has over 40 years’ experience in the sale and commissioning of test machines. Consider talking to our expert engineers, simply email sales@hyleccontrols.com.au