Komatsu has introduced the WA475-10, 26-tonne wheel loader to Australian shores, a versatile machine that combines power with Komatsu’s leading loader technology to provide an efficient and productive model for quarry and waste sites.

The WA475-10 saves 30% more on fuel efficiency than the previous model and is perfect for any hauling or loading jobs with an outstanding combination of fuel efficiency, productivity and ease of operation.

Nick Vrontas, Komatsu Australia’s National Business Manager says the significant upgrades on the WA475-10 make it an appealing addition to fleets.

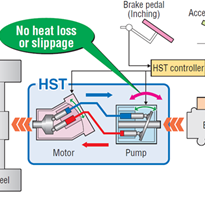

“The WA475-10 features the newly developed Komatsu’s Hydraulic Mechanical Transmission (KHMT), an innovative solution that makes the loader more powerful and more fuel-efficient. Variable speed control allows operators to adjust the machine’s top speed to meet specific site requirements, and the adjustable variable traction control also limits wheel spin on unstable and slippery ground conditions often found on many quarry and waste sites.

“We’ve also completely innovated the power control on this latest model. It’s never been easier for an operator to find the right balance between traction and lifting power, with the hydraulic speed independently controlled from the accelerator pedal, and the boom speed controlled the hydraulic lever” Nick says.

An optimised Z-bar linkage system provides much more lift force and a higher tonnes-per-hour production rate on the WA475-10, and the response time of the hydraulics and the dumping or lifting can be set to specific site requirements.

“The WA475-10 engine is Tier 4 compliant, and at even low engine speeds the engine puts out high power and delivers more engine torque and performance. The engine’s advanced electronic control system manages the airflow rate and the fuel injection, combustion parameters and aftertreatment functions, which provide optimised performance, reduced emissions, and advanced diagnostic capabilities, making it a powerful, yet environmentally friendly machine,” Nick says.

“The loader can also be tailored for specific applications, whether that is the demanding nature of a waste site, or the abrasive environments of quarries. The Komatsu team will work with customers to provide a solution that is tailored to the loader’s application, from enquiry to post delivery, maintaining service checks and requirements.

“We’re beyond excited to have the loader on our shores, and we’re looking forward to introducing it to many quarry and waste sites across the country,” Nick says.

-205x205.jpg)